|

Why Restoring Native American Pit-Fired Pottery Is Challenging

Restoring Santa Clara blackware, and other Native American pit-fired burnished clay pottery, is fundamentally

different from repairing glazed ceramics.

Burnished clay is the surface, not glaze

The defining surface of Santa Clara blackware and related Native American pit-fired pottery is not a glaze or

fired glass layer, but the clay itself. Through stone burnishing and pit firing, the clay surface is compressed,

polished, and transformed into a dense, graphite-like finish. Because there is no glaze to blend into or conceal

a repair, any disruption to that surface compression immediately reveals itself.

|

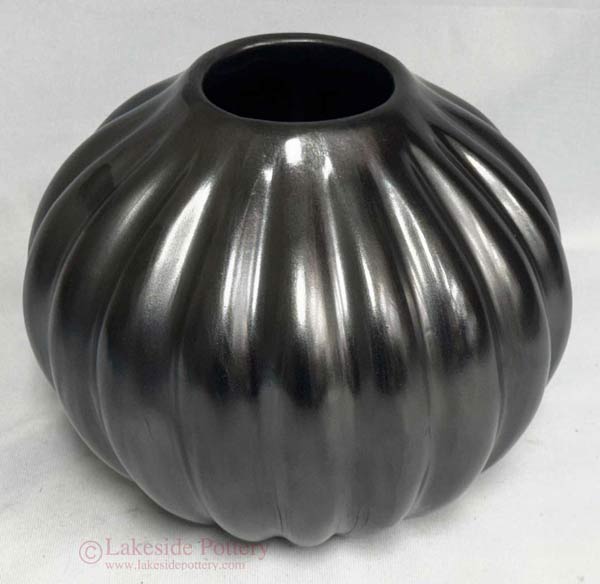

| Before restoration. Pit-fired, stone-burnished Native American pottery in multiple broken sections. The dark sheen is compressed clay, not glaze.

|

Why seamless restoration is so difficult

Even the most carefully aligned structural repair can become visible through subtle changes in reflection,

texture, or light response. Successful restoration therefore requires not only precise structural reconstruction,

but also the careful re-establishment of a surface that behaves both visually and physically like the original

burnished clay.

Surface preparation and stabilization

Cold glaze application and burnished surface recreation

Once cured, a very hard-curing epoxy cold glaze is applied using an ultra-fine airbrush mist to achieve perfectly even coverage without obscuring surface detail. Timing at this stage is critical. At the precise moment when the cold glaze is nearly fully cured but remains slightly tacky, a blend of extremely fine graphite and carefully matched pigments is applied and burnished into the surface.

The goal is to create a newly formed layer that behaves like leather-hard clay dense, compact, and responsive to burnishing allowing the repaired areas to be polished in a way that faithfully mimics the original burnished clay surface. br>

|

| Completed restoration. Final surface exhibits the density, reflection, and polish response of original burnished clay. |

|